START TYPING TO SEE PRODUCTS YOU ARE LOOKING FOR.

0

Your shopping cart is empty.

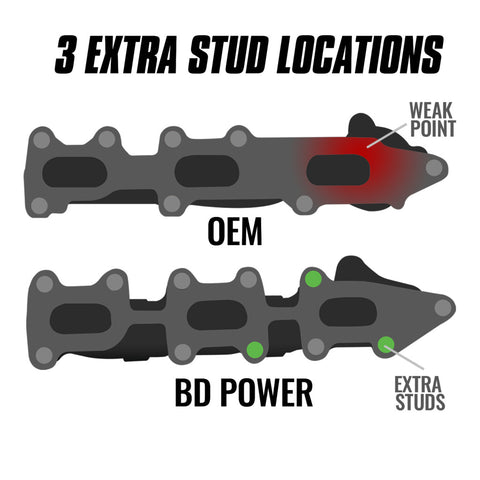

Over the past several years, the Ford EcoBoost has been growing in popularity. Starting in 2011, models of the Ford F-150 began using the 3.5L EcoBoost, providing it with power and improved fuel economy. Unfortunately there have been some issues, such as a design flaw of the OE manufacturer not using all the OE stud locations. This has resulted in warped exhaust manifolds and broken exhaust studs, as well as blown manifold gaskets.

Fine-grain cast iron is used to form the exhaust manifold. As with most metals, there is expansion and contraction during heating and cooling. This isn’t much of an issue at first. The manifold and mounting studs experience “elastic deformation,” which means that although there is deformation due to intense heat, the metal will return to its original form as it cools, much like a rubber band can be stretched but will return to normal size when released.

However, after running under load on a regular basis, the metal has been through countless cycles of extreme heating and cooling. Each cycle places stress upon the studs that hold the manifold in place. Sometimes these heat cycles can be greater than the OE intended, which leads to greater tension forces that ultimately go beyond the limits of elasticity, reaching a state known as “plastic deformation.”

At this point, the metal has expanded past the ability to regain its original form, warping it and leaving it with altered dimensions. The bolts, too, will have stretched beyond their capacity, resulting in their failure.

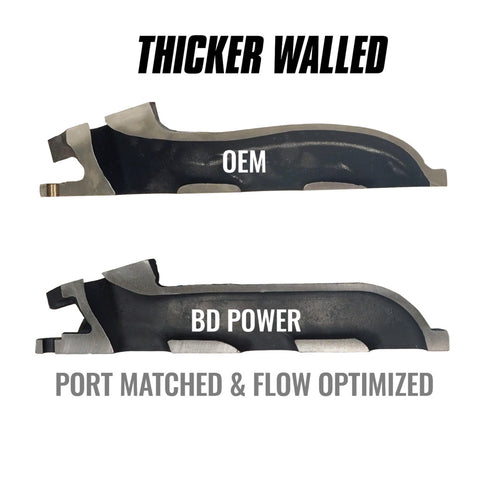

If you are replacing or upgrading your manifold, or if you have experienced exhaust leaks due to a warped manifold or broken manifold studs, BD has a solution for you, with a manifold design that uses all 11 stud locations, includes longer studs and improves exhaust flow and durability. This is the manifold as it should have come from the factory, with thicker-walled high silicon ductile iron that is resistant to warping from intense heat.

Each kit comes with 22 exhaust spacers and 22 class 8.8 studs designed to provide even greater thermal durability. Installation can be made even easier with the addition of the optional Turbo Install Kit.

Don’t risk the engine performance issues that come with a warped manifold, causing a decrease in power, acceleration, and fuel efficiency. With the BD manifold, you can avoid warping broken exhaust studs and a blown manifold gasket. Click Here for more information

Your detected location:

Please select the location that best suits you: